1. What is the Point-to-point method in assembling the vacuum tube amps?

Point-to-point (P2P) is a method of connecting electrical and electronic components in a circuit directly without using a printed circuit board (PCB). This is one of the best classic methods of making vacuum tube amplifiers because if done correctly and optimally, the amp will have the best connection quality and the amplifier will have extremely impressive durability. Because it is a manual connection method, it takes more time and effort to be assembled than the method using PCB boards.

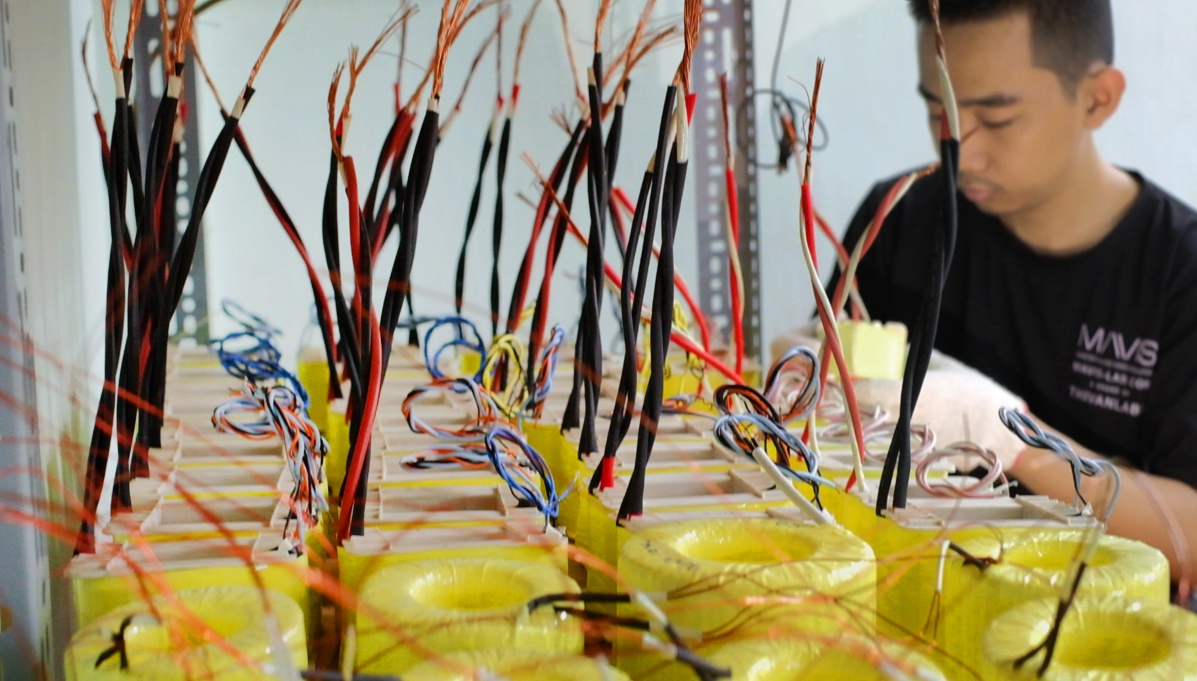

There are many ways of P2P assembly, in which the P2P method that we choose to implement for our vacuum tube amplifiers is the most labor-intensive and time-consuming method, but in return will bring a durable quality and excellent stability to the device. The P2P method used for both vacuum tube amplifiers and hybrid tube amplifiers is not only an optimal engineering but also an art requiring high aesthetic. This is not only to be beautiful inside but rather to have a neat and optimal connection of internal components which highly contribute to the long durable and stable working of the device.

For an orderly and coherent arrangement of the conductors and components inside the amp, while also achieving optimum signal transmission and ensuring the durability of component connections is not truly simple. It requires the design engineer to calculate all connections and assembly methods in the most optimal way. In addition, to achieve the comprehensive optimization of the circuit for the best sound, the best durability, the highest efficiency of use, the engineer must really have a lot of deep professional knowledge and experience in electricity – electronics as well as an aesthetic ability to achieve the integrity and optimal connection of the circuit as well as between the internal components of the device. We truly have these advantages for our vacuum tube amps!

In addition, to assemble by P2P method, it also requires the high skills of technicians along with aesthetic ability and sophistication. Therefore, this is the most expensive and ‘High End’ processing method in the world of vacuum tube amplifiers, usually only used in flagship product lines due to very expensive production costs, high requirements in terms of manpower and materials for manufacturing and assembling products.

For connoisseurs and experienced manufacturers of vacuum tube amps, the P2P assembly method in the vacuum tube amplifier is highly appreciated. Because of this strength, this assembly method is very common in amps built by Japanese engineers and in their most expensive vacuum tube amp models. Therefore, the P2P method is also used to produce Mavis’s both tube amplifiers and hybrid tube amplifiers. However, due to high processing costs, very much time-consuming and difficult to put into mass production, especially for amplifier models using high power tubes that require a high safety, not many audio manufacturers in the world choose the P2P method for their production.

The P2P method has many ways to do it and not all of them are optimal and bring the above effects. With our vacuum tube amps, we have got 15 years to evaluate the durability that our vacuum tube amps have achieved by our own P2P method. This is a confirmation of the stability as well as superiority of the P2P method we have researched and applied.

2. What is the superiority of the P2P method in our Vacuum Tube Amplifier and Hybrid Tube Amplifier?

Point to Point (P2P) method is a general definition. In fact, there are many different implementations depending on the engineer’s subjectivity. With the goal of creating high-class sound quality and long-term durability for products, we at ThivanLabs and Mavis always research and apply the most effective and optimal methods to achieve this goal.

Accordingly, the wire connection between components is always the shortest. The component pins are connected and in direct contact with each other, minimizing the addition of electrical conductors between these links. Therefore, the number of connection points is significantly reduced in the amplifier, limiting over 80% of failures during long-term use. However, this is truly a challenge for the engineers in calculating and balancing the combination of many different electronic components and techniques in the amplifier to achieve the goal of the sound quality as well as to ensure the durability of the product.

Ground plate uses a very large cross-sectional copper bar to keep ground impedance very low, through which background noise and ground loop are also significantly reduced, so the sound will be very clean, clear and delicate. Using large copper wire, although increasing production costs, but with the goal of creating the best sound and best peak stability for the device, we still decided to use high quality materials for the essential components and the core that is related to sound quality and product durability.

3. Strengths in the electronic engineering design of our vacuum tube amps and hybrid tube amps

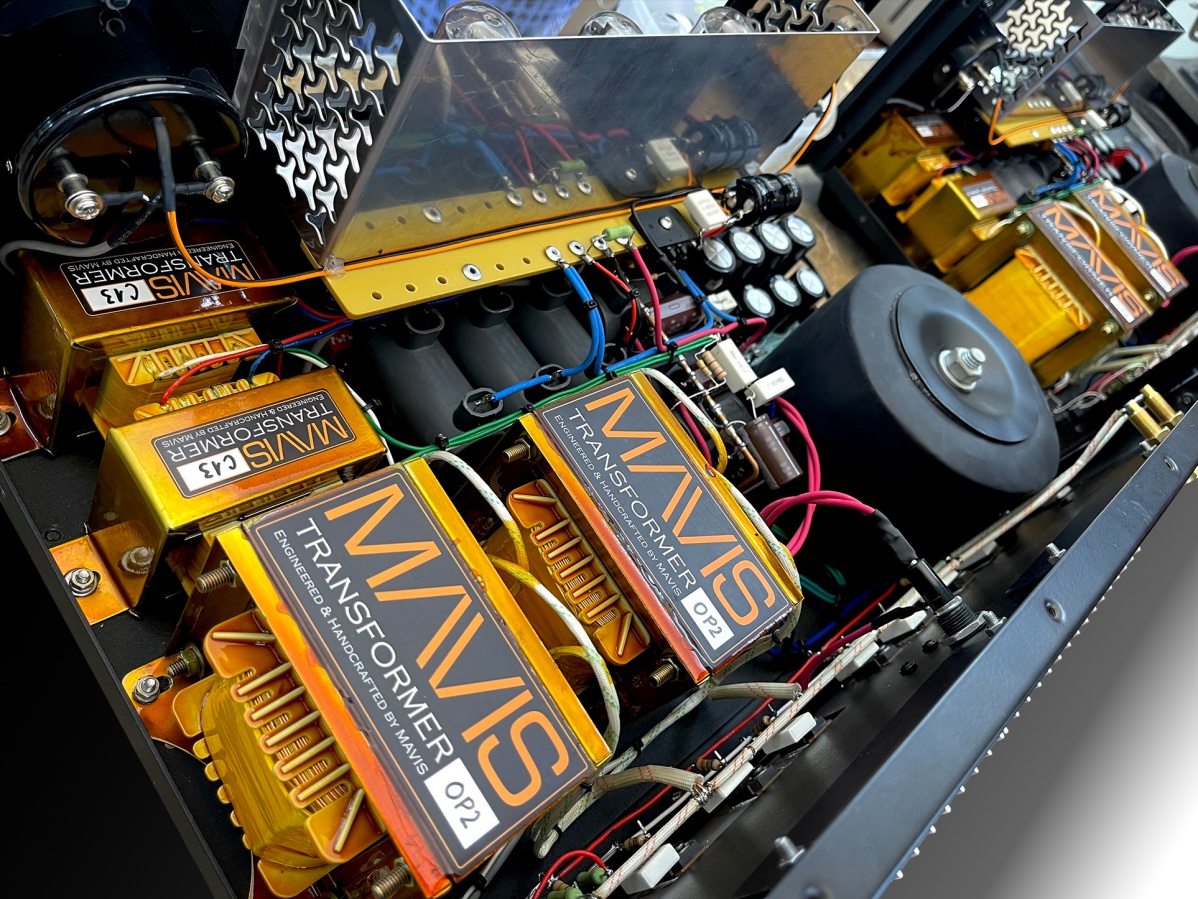

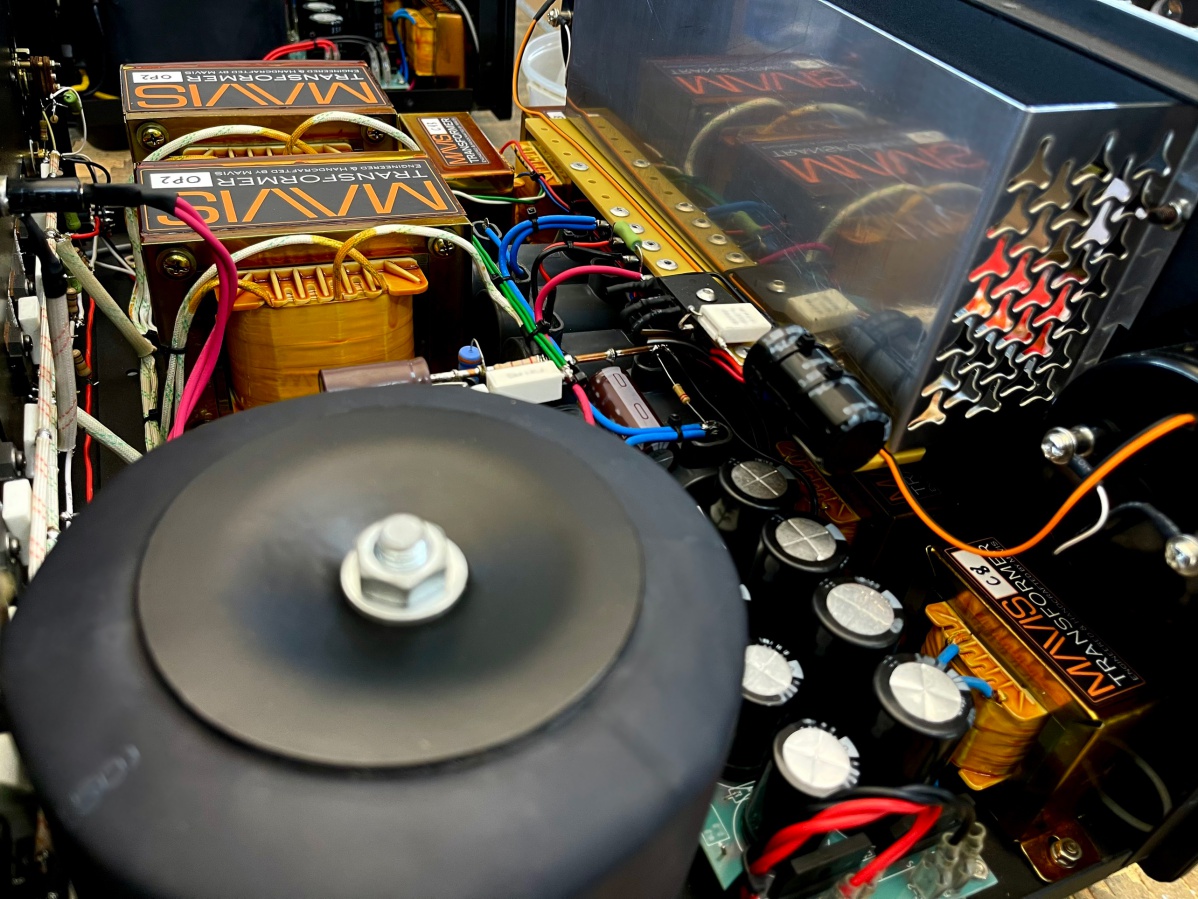

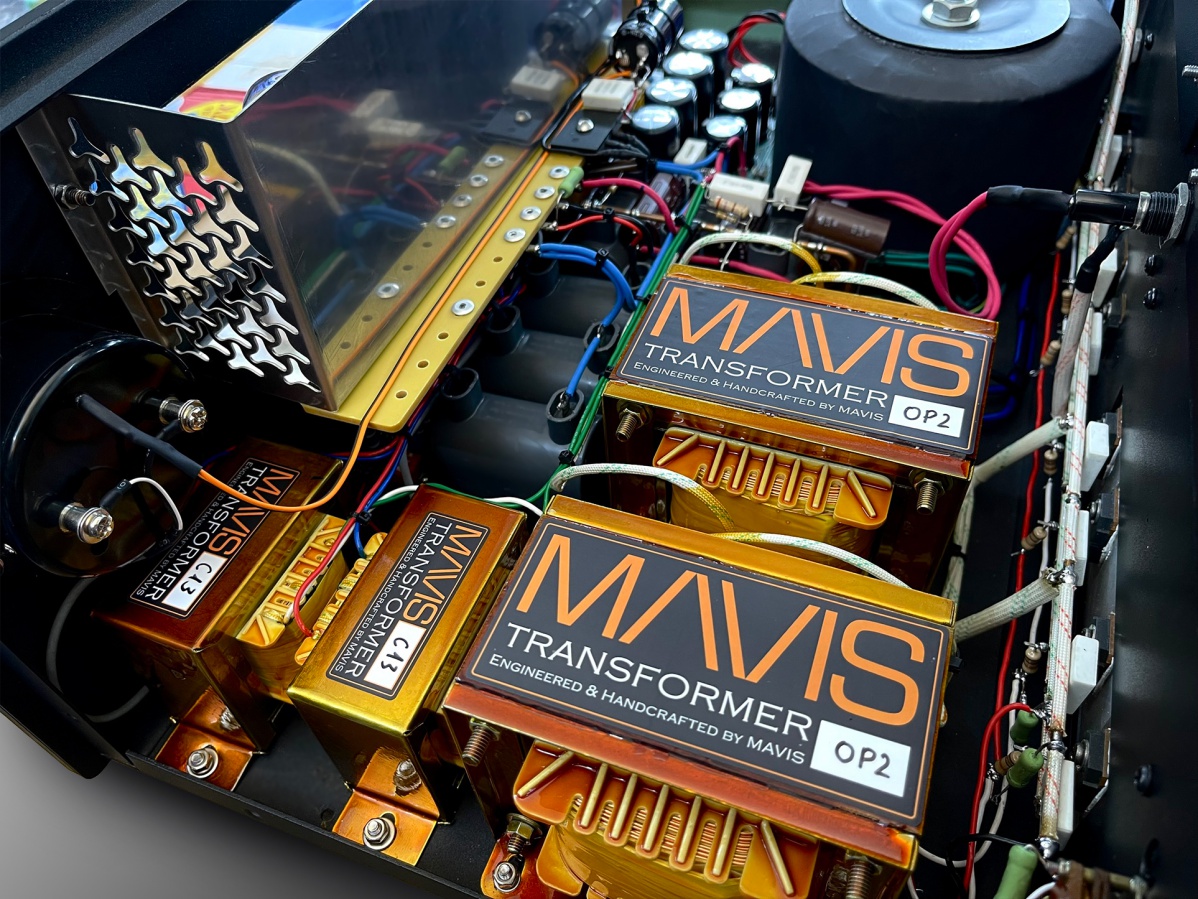

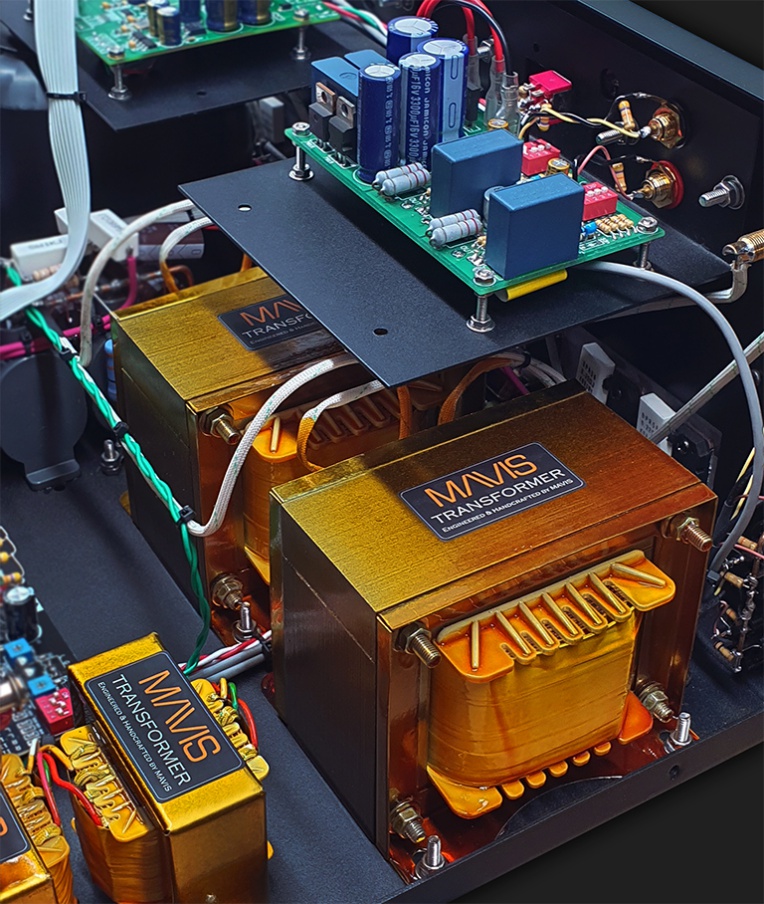

We are very proud that all our high-quality tube amps and most hybrid tube amps use our Output Transformers and Toroidal Power Transformers researched by our R&D team and manufactured in-house by high-skilled technicians. This is truly a technical achievement that our engineering team has spent many years researching and developing. It is also an important part of what makes up “the signature ThivanLabs and Mavis sound”, a sound that has already conquered many people who love natural sound and love music because of its own emotions.

– Fully use Toroidal Power Transformers: all power transformers used in ThivanLabs Amplifiers are Toroidal power transformers. Toroidal transformers are famous for having the best quality, lowest noise compared to others like EI, C-core etc. Toroidal power transformers require a complex and specialized manufacturing technique, typically only used in very high-end amplifiers.

– Fully use Toroidal Output Transformer (OPT): With our push pull amplifiers, we use the entire toroidal output transformer researched and manufactured by ThivanLabs and Mavis as a mandatory standard for the most delicate sound quality.

The output transformer (OPT) is a very important component to help transmit the audio energy from the Power vacuum tubes to the speaker. For single-ended amps, it can be said to be the most important. Over 15 years of researching and manufacturing OPT with tens of thousands of products with many different types and models used around the world, we have accumulated various practical experiences. We currently research and produce almost all types of transformers such as Toroidal Core, C-core, EI for different types of tube amplifiers such as Single Ended, Push Pull, OTL ect with power from 3W – 400W.

– Fully use Interstage Transformer (IT): Our single-ended amplifiers all use Interstage Transformer, which are directly researched by our team of knowledgeable, highly experienced electric – electronics engineers and manufactured by highly skilled technicians. The use of IT communication between the Driver and Power tubes has made the sound well controlled in all frequency ranges from bass to treble, so that the music space is open, airy, balanced and detailed.

– Always give priority to using Oil capacitors & Power choke: All of our vacuum tube amplifiers use oil capacitors and choke for the power filter circuit of the power stage as a mandatory standard to bring the cleanest sound, the best music performance as well as stability, safety and durability of the amp. Oil capacitors and power choke are also choices with very high material and processing costs in production, but sound quality and product durability are always our top priority, so we still decide to use them.

4. Auto Bias – Another strength of our vacuum tube amps and hybrid tube amps in the use

In order to bring the most convenience and ease to the user, all of our current vacuum tube amplifiers and hybrid tube amplifiers have been designed to have the tubes operate in Auto Bias mode. Accordingly, non-technical users can still easily replace the tubes without having to adjust the device, nor need to select the Bias mode, but it is extremely simple to just unplug and plug in the equivalent tubes to use immediately.

Unlike some tube amplifiers that Auto Bias circuits are designed to use current source with trendy semiconductor components which easily add the various colors to the sound, we still stick to the most classic Auto Bias design to keep the authentic, original warm sound of electronic vacuum tubes. Additionally, using many modern semiconductor components brings a temporary attractive look but when damaged, it is very difficult to repair. We always try to avoid this.

5. Zero Feedback – The sonic advantage of our vacuum tube amps and hybrid tube amps

Using Feedback or not using Feedback?

That’s the question all engineers and manufacturers have to choose. This is like a choice between “beautiful parameters” and “fine music”. Using much feedback makes it easy to achieve high specifications such as broadband up to 10Hz-100kHz, low THD harmonic distortion, so many engineers have chosen this option for beautiful measurements and easy for marketing.

However, overusing the Feedback technique without understanding the music and the working of components such as triode, pentode, transistor, mosfet etc in amplifying and reproducing sound in an electronic circuit will create a product that is beautiful in terms of measurement parameters but poor in music and the emotions of the music. With a team of engineers highly trained in electronics, achieving beautiful measurements is a basic standard that all ThivanLabs and Mavis amps must achieve. Moreover, not only do they have good measurement parameters, all of our vacuum tube amplifier models and hybrid tube amplifier models now have Zero Feedback standard to prioritize the natural reproduction of the sound and performing music with the best musicality and emotion.

In the field of vacuum tube amplification, after 15 years of research, testing and improvement, all of our current ThivanLabs and Mavis products have achieved wide bandwidth, low harmonic distortion, extremely low noise, and still retain the best music quality with Zero Feedback standard. For veteran fans of vacuum tube amps, who have experienced many audio products, the amps with Zero Feedback are always the first choice. Mavis hybrid tube amplification also inherited this great standard.